Tyre sealant bottle

TIREFIT sticker

Sticker with details of the maximum permissible speed

Tyre inflation compressor

Gloves

TIREFIT kit storage location: More

You can use TIREFIT tyre sealant to seal perforation damage of up to 4 mm, particularly those in the tyre contact surface. You can use TIREFIT in outside temperatures down to -20 °C.

The tyre sealant may be unable to seal the tyre properly, especially in the following cases:

there are cuts or punctures in the tyre larger than damage previously mentioned.

the wheel rim is damaged.

you have driven at very low tyre pressures or on a flat tyre.

Tyre sealant is hazardous to health and causes irritation. Do not allow it to come into contact with your skin, eyes or clothing, and do not swallow it. Do not inhale any vapours. Keep the tyre sealant away from children.

Observe the following if you come into contact with the tyre sealant:

Comply with the manufacturer's safety notes on the sticker on the tyre sealant bottle.

Have the tyre sealant bottle replaced in a qualified specialist workshop every five years.

from the tyre inflation compressor housing and affix it to the instrument cluster within the driver's field of vision.

from the tyre inflation compressor housing and affix it to the instrument cluster within the driver's field of vision.

from the tyre sealant bottle and affix it near the valve on the wheel with the defective tyre.

from the tyre sealant bottle and affix it near the valve on the wheel with the defective tyre.

with the cable and filler hose

with the cable and filler hose  out of the tyre inflation compressor housing.

out of the tyre inflation compressor housing.  in socket

in socket  of the tyre inflation compressor in such a way that the red arrow on tyre sealant bottle

of the tyre inflation compressor in such a way that the red arrow on tyre sealant bottle  matches the red arrow on the tyre inflation compressor.

matches the red arrow on the tyre inflation compressor.  a quarter turn clockwise.

a quarter turn clockwise.  in socket

in socket  of tyre sealant bottle

of tyre sealant bottle  .

.  a quarter turn clockwise.

a quarter turn clockwise.

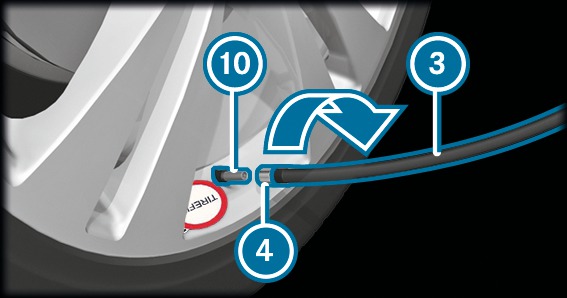

on the faulty tyre.

on the faulty tyre.  of filler hose

of filler hose  onto valve

onto valve  .

.

into a 12 V socket in your vehicle.

into a 12 V socket in your vehicle.  in the ignition lock.

in the ignition lock.  on the tyre inflation compressor.

on the tyre inflation compressor. The tyre inflation compressor is switched on. The tyre is inflated. First, tyre sealant is pumped into the tyre. The pressure may briefly rise to approximately 500 kPa (5 bar/73 psi).

Do not switch off the tyre inflation compressor during this phase!

The tyre should then have attained a tyre pressure of at least 200 kPa (2.0 bar/29 psi).

If tyre sealant leaks out, make sure you clean the affected area as quickly as possible. It is preferable to use clean water.

If you get tyre sealant on your clothing, have it cleaned as soon as possible with perchloroethylene.

Please note that tyre sealant may leak out when unscrewing the filling hose.

After a maximum of ten minutes the tyre pressure must be at least 200 kPa (2.0 bar/29 psi).

If the minimum tyre pressure is not reached after the specified time, the tyre is too badly damaged. The tyre sealant cannot repair the tyre in this instance.

The braking and driving characteristics may be greatly impaired.

After use, excess tyre sealant may leak out from the filling hose.

Please note that tyre sealant may leak out when unscrewing the filling hose.

A tyre temporarily sealed with tyre sealant impairs the handling characteristics and is not suitable for higher speeds.

After use, excess tyre sealant may leak out from the filling hose.

Tyre sealant contains pollutants.

The tyre pressure must now be at least 130 kPa (1.3 bar/19 psi).

If the specified tyre pressure is not reached, the tyre is too badly damaged. The tyre sealant cannot repair the tyre in this instance.

The braking and driving characteristics may be greatly impaired.

Countries that have Mercedes-Benz Service24h: you will find a sticker with the telephone number, e.g. on the B‑pillar on the driver's side.

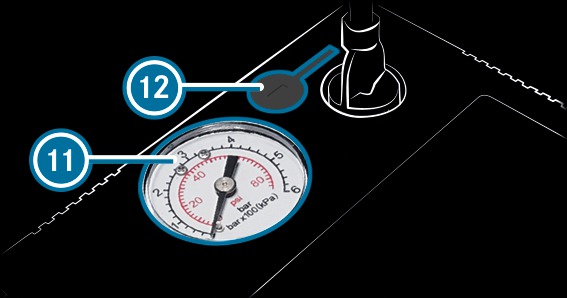

next to manometer

next to manometer  .

.